Anode host with liquid electrolyte

Polypropylene Separator

Cathode with liquid electrolyte

Li-ion cells generally have a composite cathode and a graphite-host anode separated by an inactive polymer. Liquid electrolyte is injected to facilitate ionic transfer.

Lithium metal anode

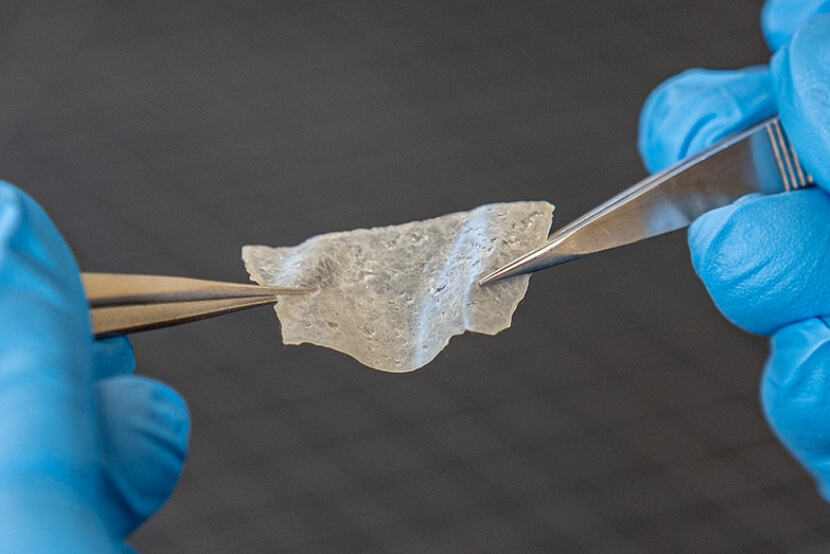

Solid electrolyte separator

Cathode with solid electrolyte

Nuvvon has developed a solid polymer electrolyte that is both the active separator and in the cathode. A lithium metal anode plates and strips lithium to charge and discharge the battery.

Our goal is to create a safer battery that can replace graphite with lithium metal, thereby increasing energy density. Lithium stability is a challenge and compatible electrolytes often require high pressure, high temperature or require new manufacturing methods - we have overcome these obstacles at lab scale and are starting to scale up in size and volume.

Ceramic electrolytes have high interfacial resistance requiring enormous pressure and/or the use of liquids, increasing risk

Our solid polymer electrolyte does not require pressure or liquid.

Liquid electrolytes can become unstable above 40ºC, while most traditional solid polymers electrolytes cannot operate below 70ºC

Our solid polymer electrolyte operates at room temperature and high temperature.

Many electrolytes are unstable with lithium metal and most are unstable with high voltage cathodes such as LNMO.

Our solid polymer electrolyte is stable with lithium metal and LNMO.

Batteries using ceramics and multiple novel technologies will be more difficult to produce on existing equipment.

Our solid-state pouch cells are produced on standard Li-ion equipment.

Our unique technology makes our cells remarkably simple and a short-term reality, which is why we are years ahead.

Our time frame?

With next stage investment we will produce commercial grade cells on a standard MWh production line within 12-18 months.

All substances will burn with sufficient heat, but Nuvvon solid polymer electrolytes resist thermal runaway when exposed to a naked flame and when used at high operating temperature.

Flexibility is critical for roll-to-roll technology. Nuvvon solid polymer electrolytes have been purposefully designed for standard Li-ion production equipment using R2R processes.

Strength is important for processing and performance. Nuvvon’s separator electrolyte layer has a high Youngs Modulus to help withstand dendrite penetration.

Nuvvon Inc and The Rutgers EcoComplex jointly announce Nuvvon Inc.’s move from the EcoComplex to their new facility.

Our Head of Innovation, Manveer Sidhu, introduces our brand new laboratory in Parsippany and discusses Nuvvon’s mission to revolutionize the field of energy storage.

Next-Generation Battery Innovator Nuvvon announces new state-of-the-art laboratory in Parsippany, New Jersey.